Semiconductor and special solutions

Semiconductor and special solutions

Our Shop offers a variety of spare parts for the following machines: DNS 80 / 60B, Coater, Developer or Scrubber.

|

|

|

|

|

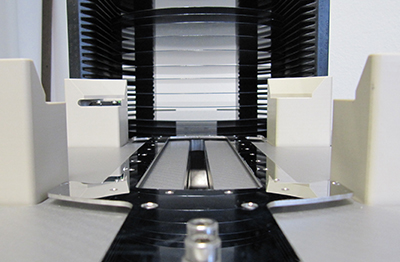

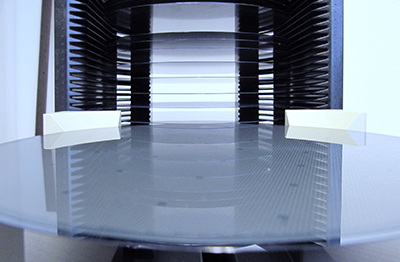

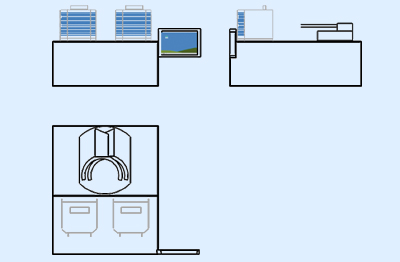

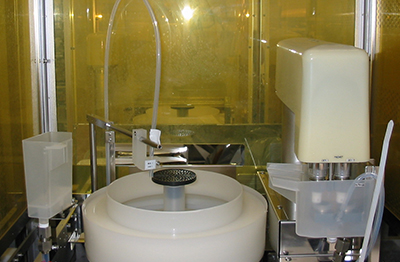

NEW: The  Waferpresenter

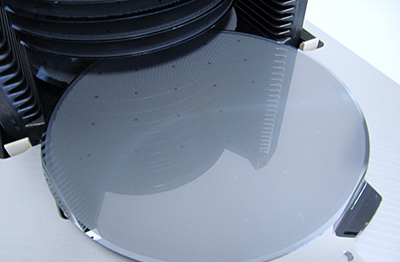

Waferpresenter

Examples of applications of the

REA-tronic® Waferpresenter:

- Visual inspection

- Cassette re- sorting

- Microscope and machine implementation

- No scratching during selecting

- Easy choice of slots through selection of large touch display

- Safe placement of the wafer in front of the cassette

- Quicker processing through automatic choice

You can call us at:

+43(0) 662/ 66 10 77

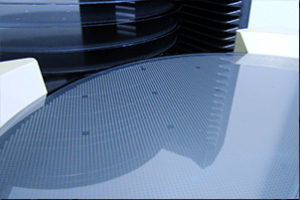

Refurbished DNS80B

REA-tronic® is the specialist for refurbished DNS track

- Refurbishment of the Tracks according to OEM specifications

- Various installation of machines according to customer wishes

- Space – saving design change of the tracks

- Service and set up of the machines through REA-tronic®

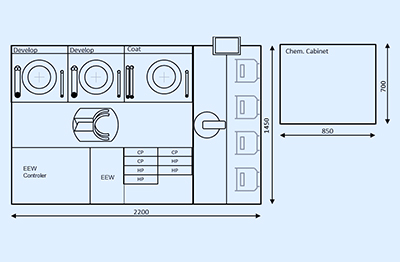

1 Coater / 2 Developer

4 Load/Unload Ports

4 Hotplates 4 Coolplates

1 EEW Edge Exposure Unit

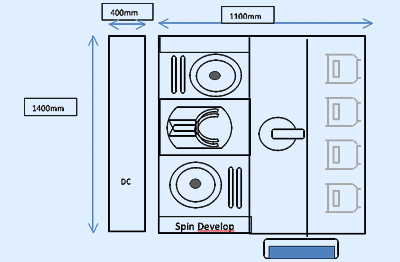

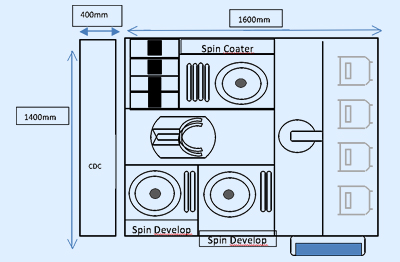

2 Developer / 4 Load/Unload Ports

4 Load/Unload Ports /2 Developer (2 Spray Nozzles)

1 Coater (4 Resist Nozzles; IDI Pump 300 / 450)

2 Hotplates 180°C / 2 Coolplates

Model: 80SK BW-AVPE for 6”/8” (150mm/200mm) Wafer

Technical Data:

Type: REA-tronic® RTC WL 022

Model: Arm for (150mm/200mm) Wafer

Dimension: 700 mm x 700 mm x 600 mm

Touchscreen: 370 mm x 170 mm x 360 mm

Control-PC: 180 mm x 500 mm x 400 mm.

You can call us at:

+43(0) 662/ 66 10 77

Convac Fairchild Coater

convac Fairchild Coater Broschüre

>>Download

Type: CBA 3 – 3 M 2000 Year: 09/1996

Lithographic process system with high throughput, flexible wafer flow and modular design with small footprint. Process modules with pick and place robot handling for substrates up to 150mm diameter Convac

Coater with 3 independent wafer line

2 input stations (on the right side)

1 spin unit for up to 3 resists

2 bake unit,

1 coolplate and

2 receiving stations

3 Solvent pumps and pump controller

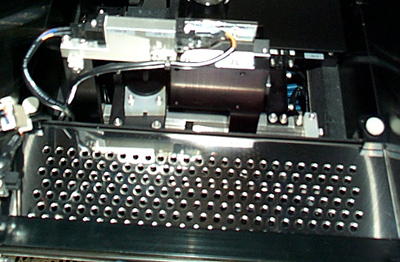

DNS Spin Motor Repair

We repair all Spin Motors of the brand which are built in DNS Tracks.

- DNS 60A Coat, Developer or Scrubber

- DNS 80A Coat, Developer or Scrubber

- DNS 60B Coat, Developer or Scrubber

- DNS 80B Coat, Developer or Scrubber

Refurbishment

REA-tronic® Refurbished machine components of DNS Tracks. Nearly all components are tested after the refurbishment on the machine in similar situations to the process. We stock many spare parts which are sent as exchange units.

Artikel aus dem Refurbishment Sortiment:

- Heat exchanger

- Chemical Controller

- Spin Motor Controller

- IDI Pumpen 300 / 350 / 450